生物技术进展 ›› 2024, Vol. 14 ›› Issue (6): 1032-1041.DOI: 10.19586/j.2095-2341.2024.0108

孔蒙蒙( ), 金静静, 卢鹏, 顾梦丽, 陈千思, 曹培健, 张剑锋, 陶界锰(

), 金静静, 卢鹏, 顾梦丽, 陈千思, 曹培健, 张剑锋, 陶界锰( )

)

收稿日期:2024-05-27

接受日期:2024-07-08

出版日期:2024-11-25

发布日期:2024-12-27

通讯作者:

陶界锰

作者简介:孔蒙蒙 E-mail: 2477658055@qq.com;

基金资助:

Mengmeng KONG( ), Jingjing JIN, Peng LU, Mengli GU, Qiansi CHEN, Peijian CAO, Jianfeng ZHANG, Jiemeng TAO(

), Jingjing JIN, Peng LU, Mengli GU, Qiansi CHEN, Peijian CAO, Jianfeng ZHANG, Jiemeng TAO( )

)

Received:2024-05-27

Accepted:2024-07-08

Online:2024-11-25

Published:2024-12-27

Contact:

Jiemeng TAO

摘要:

为提高工程菌株纤维素酶产酶效率,采用单因素试验和正交试验法对高产纤维素酶枯草芽孢杆菌(Bacillus subtilis)工程菌株C36、CM、KF、GH5的发酵培养基和培养条件进行优化。结果表明,工程菌株C36、CM、KF和GH5在最优发酵条件下的产酶效率显著提高。发酵条件优化后,工程菌株CM的纤维素酶活最高,在醇化烟叶添加量7%、蛋白胨添加量0.8%、pH 6.1、发酵温度37 ℃、转速220 r·min-1、装液量40 mL及发酵时间96 h的条件下,其羧甲基纤维素(carboxymethylcellulose, CMC)酶活和滤纸酶活(filter paper activity, FPA)分别达到504.95和222.11 U·mL-1。发酵条件优化后,工程菌株GH5的纤维素酶活提升倍数最高,在醇化烟叶添加量6%、蛋白胨添加量0.9%、pH 6.1、发酵温度37 ℃、转速220 r·min-1、装液量40 mL及发酵时间96 h的条件下,其CMC和FPA酶活分别是优化前的28.55和9.68倍。

中图分类号:

孔蒙蒙, 金静静, 卢鹏, 顾梦丽, 陈千思, 曹培健, 张剑锋, 陶界锰. 高产纤维素酶工程菌株产酶条件优化[J]. 生物技术进展, 2024, 14(6): 1032-1041.

Mengmeng KONG, Jingjing JIN, Peng LU, Mengli GU, Qiansi CHEN, Peijian CAO, Jianfeng ZHANG, Jiemeng TAO. Optimization of Enzyme Production Conditions of High-yielding Cellulase Engineering Strains[J]. Current Biotechnology, 2024, 14(6): 1032-1041.

| 水平 | A:碳源/% | B:氮源/% | C:初始pH |

|---|---|---|---|

| 1 | 5 | 0.8 | 5.5 |

| 2 | 6 | 0.9 | 6.1 |

| 3 | 7 | 1.0 | 6.6 |

表1 发酵培养基条件正交试验因素与水平

Table 1 Factors and levels of orthogonal experiments for fermentation medium conditions

| 水平 | A:碳源/% | B:氮源/% | C:初始pH |

|---|---|---|---|

| 1 | 5 | 0.8 | 5.5 |

| 2 | 6 | 0.9 | 6.1 |

| 3 | 7 | 1.0 | 6.6 |

| 水平 | D:发酵温度/℃ | E:转速/(r·min-1) | F:装液量/mL | G:发酵时间/h |

|---|---|---|---|---|

| 1 | 34 | 180 | 40 | 72 |

| 2 | 37 | 200 | 80 | 96 |

| 3 | 40 | 220 | 100 | 120 |

表2 发酵培养条件正交试验因素与水平

Table 2 Factors and levels of orthogonal experiments for fermentation culture conditions

| 水平 | D:发酵温度/℃ | E:转速/(r·min-1) | F:装液量/mL | G:发酵时间/h |

|---|---|---|---|---|

| 1 | 34 | 180 | 40 | 72 |

| 2 | 37 | 200 | 80 | 96 |

| 3 | 40 | 220 | 100 | 120 |

图1 不同碳源和氮源对工程菌株纤维素酶活的影响A~B:不同碳源对工程菌株CMC和FPA酶活的影响;C~D:不同氮源对工程菌株CMC酶活和FPA酶活的影响;同一菌株不同处理上的不同小写字母表示在P<0.05水平上具有统计学意义。

Fig. 1 Effects of different carbon and nitrogen sources on cellulase activity of engineered strains

图2 不同碳源添加量、氮源添加量、初始pH对工程菌株纤维素酶活的影响A、B:不同醇化烟叶添加量对工程菌株CMC酶活和FPA酶活的影响;C、D:不同蛋白胨添加量对工程菌株CMC酶活和FPA酶活的影响;E、F:不同初始pH对工程菌株CMC酶活和FPA酶活的影响

Fig. 2 Effects of different additions of carbon source and nitrogen source and different initial pH values on cellulase activities of engineered strains.

| 正交编号 | A:醇化烟叶 | B:蛋白胨 | C:pH |

|---|---|---|---|

| 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 3 |

| 3 | 1 | 3 | 2 |

| 4 | 2 | 1 | 3 |

| 5 | 2 | 2 | 2 |

| 6 | 2 | 3 | 1 |

| 7 | 3 | 1 | 2 |

| 8 | 3 | 2 | 1 |

| 9 | 3 | 3 | 3 |

表3 C36、CM、KF和GH5发酵培养基正交试验表

Table 3 Orthogonal test of fermentation medium conditions for C36, CM, KF and GH5

| 正交编号 | A:醇化烟叶 | B:蛋白胨 | C:pH |

|---|---|---|---|

| 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 3 |

| 3 | 1 | 3 | 2 |

| 4 | 2 | 1 | 3 |

| 5 | 2 | 2 | 2 |

| 6 | 2 | 3 | 1 |

| 7 | 3 | 1 | 2 |

| 8 | 3 | 2 | 1 |

| 9 | 3 | 3 | 3 |

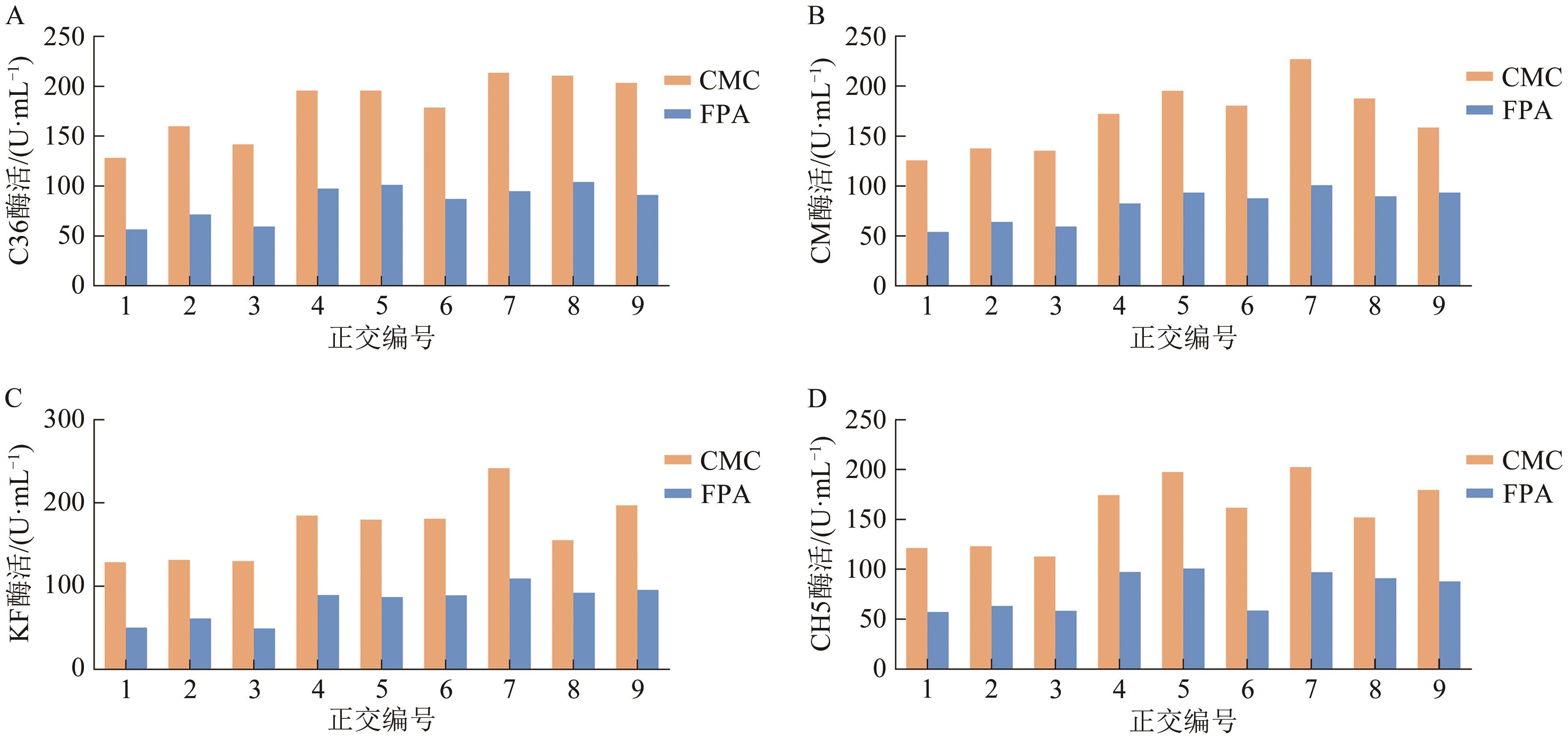

图3 菌株发酵培养基优化正交实验结果A:C36正交实验结果;B:CM正交实验结果;C:KF正交实验结果;D:GH5正交实验结果

Fig. 3 Results of orthogonaltests on the optimization of fermentation medium for strains

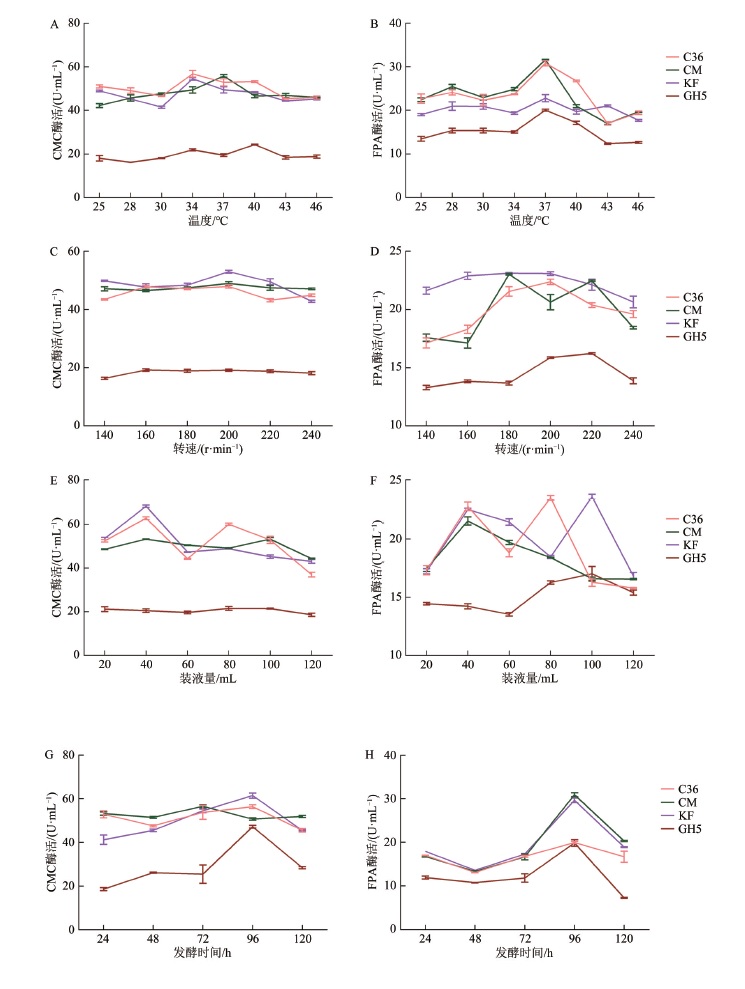

图4 不同培养条件对工程菌株纤维素酶酶活的影响A、B:不同温度对工程菌株CMC酶活和FPA酶活的影响;C、D:不同摇床转速对工程菌株CMC酶活和FPA酶活的影响;E、F:不同装液量对工程菌株CMC酶活和FPA酶活的影响;G、H:不同发酵时间工程菌株CMC酶活和FPA酶活

Fig. 4 Effects of different culture conditions on cellulase activities of engineered strains

| 编号 | D:发酵温度 | E:转速 | F:装液量 | G:发酵时间 |

|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 | 2 |

| 3 | 1 | 3 | 3 | 3 |

| 4 | 2 | 1 | 2 | 3 |

| 5 | 2 | 2 | 3 | 1 |

| 6 | 2 | 3 | 1 | 2 |

| 7 | 3 | 1 | 3 | 2 |

| 8 | 3 | 2 | 1 | 3 |

| 9 | 3 | 3 | 2 | 1 |

表4 C36、CM、KF和GH5发酵培养条件正交实验表

Table 4 Orthogonal test of fermentation culture conditions for C36, CM, KF and GH5

| 编号 | D:发酵温度 | E:转速 | F:装液量 | G:发酵时间 |

|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 | 2 |

| 3 | 1 | 3 | 3 | 3 |

| 4 | 2 | 1 | 2 | 3 |

| 5 | 2 | 2 | 3 | 1 |

| 6 | 2 | 3 | 1 | 2 |

| 7 | 3 | 1 | 3 | 2 |

| 8 | 3 | 2 | 1 | 3 |

| 9 | 3 | 3 | 2 | 1 |

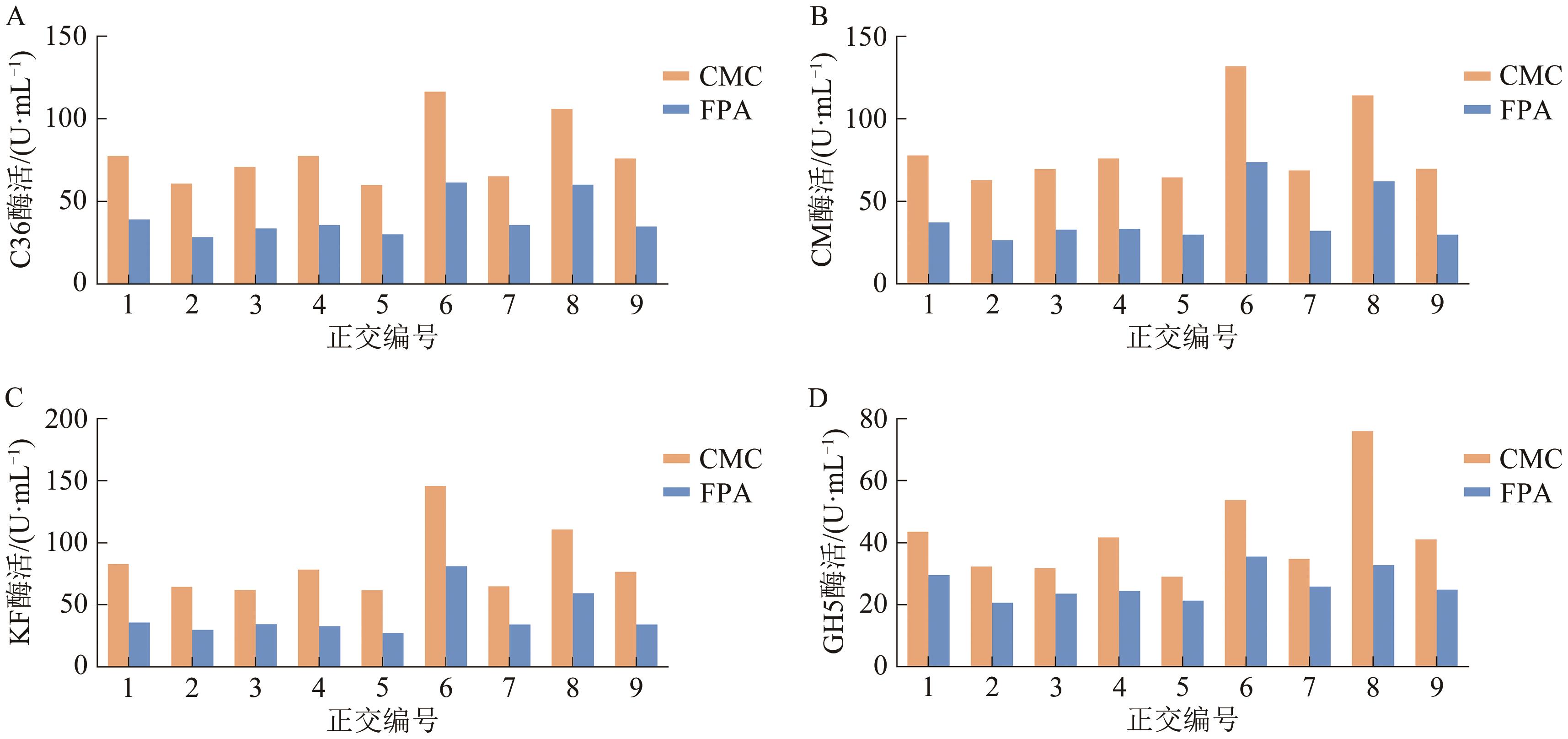

图5 菌株发酵培养条件优化正交实验结果A:C36正交实验结果;B:CM正交实验结果;C:KF正交实验结果;D:GH5正交实验结果

Fig. 5 Results of orthogonal tests on the optimization of fermentation conditions for strains

| 菌株 | 醇化烟叶/% | pH | 蛋白胨/% | 发酵温度/℃ | 转速/(r·min-1) | 装液量/mL | 发酵时间/h | CMC酶活/(U·mL-1) | FPA酶活/(U·mL-1) |

|---|---|---|---|---|---|---|---|---|---|

| C36 | 7 | 5.5 | 0.9 | 37 | 220 | 40 | 96 | 542.95 | 191.03 |

| CM | 7 | 6.1 | 0.8 | 37 | 220 | 40 | 96 | 504.95 | 222.11 |

| KF | 7 | 6.1 | 0.8 | 37 | 220 | 40 | 96 | 545.57 | 193.98 |

| GH5 | 6 | 6.1 | 0.9 | 37 | 220 | 40 | 96 | 530.78 | 193.76 |

表5 C36、CM、KF和GH5的最优发酵条件下的酶活

Table 5 Cellulase activities under the optimal combinations of C36, CM, KF and GH5

| 菌株 | 醇化烟叶/% | pH | 蛋白胨/% | 发酵温度/℃ | 转速/(r·min-1) | 装液量/mL | 发酵时间/h | CMC酶活/(U·mL-1) | FPA酶活/(U·mL-1) |

|---|---|---|---|---|---|---|---|---|---|

| C36 | 7 | 5.5 | 0.9 | 37 | 220 | 40 | 96 | 542.95 | 191.03 |

| CM | 7 | 6.1 | 0.8 | 37 | 220 | 40 | 96 | 504.95 | 222.11 |

| KF | 7 | 6.1 | 0.8 | 37 | 220 | 40 | 96 | 545.57 | 193.98 |

| GH5 | 6 | 6.1 | 0.9 | 37 | 220 | 40 | 96 | 530.78 | 193.76 |

| 1 | 李鹏,陈秀珍,庄文颖.高产纤维素酶的拟康宁木霉菌株8985固态发酵条件优化[J].菌物学报,2021,40(4):743-758. |

| LI P, CHEN X Z, ZHUANG W Y. Optimization of solid state fermentation conditions for the high cellulase producing strain Trichoderma koningiopsis 8985[J]. Mycosystema, 2021, 40(4): 743-758. | |

| 2 | 李昌珠,蒋丽娟,陈景震,等.产维素酶菌株SB-4的理化特性及产酶条件优化[J].湖南林业科技,2017,44(6):40-44. |

| LI C Z, JIANG L J, CHEN J Z, et al.. Physiological and biochemical properties of a strain producing cellulose SB-4 and optimization of conditions for enzyme production[J]. Hunan For. Sci. Technol., 2017, 44(6): 40-44. | |

| 3 | 姜立春,赵丽萍,林寿露,等.纤维素降解菌的筛选、鉴定与产酶条件优化试验[J].黑龙江畜牧兽医(上半月),2017(6):166-172. |

| JIANG L C, ZHAO L P, LIN S L, et al.. Screening, identification and optimization of enzyme production conditions of cellulose-degrading bacteria[J/OL]. Heilongjiang Animal Husb. Vet. Sci., 2017(6): 166-172. | |

| 4 | 陈兴,王文元,汪显国,等.烟叶纤维素降解菌的筛选、鉴定及其产酶条件优化[J].云南大学学报(自然科学版),2015,37(2):323-328. |

| CHEN X, WANG W Y, WANG X G, et al.. Screening, identification of cellulose-decomposing strain from aging flue-cured tobacco leaves and optimization of its fermentation condition[J]. J. Yunnan Univ. Nat. Sci. Ed., 2015, 37(2): 323-328. | |

| 5 | 赵鑫,张红,门中华,等.纤维素酶的研究与应用进展[J].化学与生物工程,2023,40(9):1-9. |

| ZHAO X, ZHANG H, MEN Z H, et al.. Research and application progress in cellulase[J]. Chem. Bioeng., 2023, 40(9): 1-9. | |

| 6 | DATTA R, KELKAR A, BARANIYA D, et al.. Enzymatic degradation of lignin in soil: a review[J/OL]. Sustainability, 2017, 9(7): 1163[2024-07-25]. . |

| 7 | NEJLA B. E, MINNA H. Degradation of cellulose derivatives in laboratory, man-made, and natural environments[J]. Biomacromolecules, 2022,23(7):2713-2729. |

| 8 | 李秀妮,李猛,万德建,等.烟叶微生物及其在烟叶发酵和醇化中的作用研究进展[J].微生物学通报,2019,46(6):1520-1529. |

| LI X N, LI M, WAN D J, et al.. Role of microorganisms in tobacco fermentation and alcoholization: a review[J]. Microbiol. China, 2019, 46(6): 1520-1529. | |

| 9 | 关亮,李天丽,陈竹亭,等.陈化烟叶中纤维素降解菌群的分离及其特性研究[J].中国烟草科学,2013,34(6):103-107. |

| GUAN L, LI T L, CHEN Z T, et al.. Isolation and characterization of bacterial community with cellulose-decomposition ability from aging flue-cured tobacco leaves[J]. Chin. Tob. Sci., 2013, 34(6): 103-107. | |

| 10 | LIU F, WU Z Y, ZHANG X P, et al.. Microbial community and metabolic function analysis of cigar tobacco leaves during fermentation[J]. Microbiol. Open, 2021, 10(2): 1171. |

| 11 | 孔蒙蒙,卢鹏,陈千思,等. 产纤维素酶工程菌株的构建及其在醇化烟叶中的应用[J]. 生物技术进展, 2024, 14(2): 263-270. |

| KONG M M, LU P, CHEN Q S, et al.. Construction of cellulase producing strain and its application in alcoholized tobacco leaves[J]. Curr, Biotechnol., 2024, 14(2): 263-270. | |

| 12 | ZHANG G H, LU Z, WEI L, et al.. Changes in physicochemical properties and microbial community succession during leaf stacking fermentation[J/OL]. AMB Express, 2023, 13: 1-15[2024-07-20]. . |

| 13 | ZHANG Q, KONG G H, ZHAO G K, et al.. Microbial and enzymatic changes in cigar tobacco leaves during air-curing and fermentation[J]. Appl. Microbiol. Biotechnol., 2023, 107(18): 1-13. |

| 14 | 陆晨.高产纤维素酶菌株的筛选及其产酶条件的优化[D].长沙:中南林业科技大学,2012. |

| 15 | 钟斌,陶文玲,倪思毅,等. 一株纤维素降解菌的筛选、鉴定及产酶条件优化[J]. 江西农业大学学报,2021,43(05):1167-1177. |

| ZHONG B, TAO W L, NI S Y, et al.. Screening, identification and optimization of enzyme production conditions of a cellulose degrading bacterium[J]. J. Jiangxi Agric. Univ., 2021, 43(05): 1167-1177. | |

| 16 | 李鹏,陈秀珍,庄文颖.高产纤维素酶的拟康宁木霉菌株8985固态发酵条件优化[J].菌物学报,2021,40(4):743-758. |

| LI P, CHEN X Z, ZHUANG W Y. Optimization of solid state fermentation conditions for the high cellulase producing strain Trichoderma koningiopsis 8985[J]. Mycosystema, 2021, 40(4): 743-758. | |

| 17 | 李春梅,何江波,陈惠,等. 高产中性纤维素酶的巨大芽孢杆菌基因工程菌发酵工艺条件优化[J]. 农业生物技术学报,2011,19(03):557-564. |

| LI C M, HE J B, CHEN H, et al.. Optimization of fermentation process conditions of genetically engineered Bacillus gigantium with high yield of neutral cellulase[J]. Chin. J. Agric. Biotechnol., 2011, 19(03): 557-564. | |

| 18 | 张远科,徐鸿,曹治,等.产纤维素酶细菌的筛选及其产酶优化[J].纤维素科学与技术,2021,29(3):16-26. |

| ZHANG Y K, XU H, CAO Z, et al.. Screening of cellulase-producing bacteria and optimization of enzyme production[J]. J. Cellul. Sci. Technol., 2021, 29(3): 16-26. | |

| 19 | 王永伦,余克非,郑展望.1株耐高温纤维素降解菌发酵条件优化与秸秆降解应用[J].江苏农业科学,2023,51(19):229-236+244. |

| WANG Y L, YU K F, ZHENG Z W. Optimization of fermentation conditions and application of straw degradation of a strain resistant to high temperature cellulose[J]. Jiangsu Agric. Sci., 2019, 51(19): 229-236+244. | |

| 20 | 周宁,王智伟,曹平华,等.产酸性木聚糖酶链霉菌的鉴定、酶学特性及发酵工艺研究[J].中国饲料,2016(8):16-21+24. |

| ZHOU N, WANG Z W, CAO P H, et al.. Identification, enzymatic characteristics and fermentation technology of Streptomyces xylanase producing acid[J/OL]. China Feed, 2016(8): 16-21+24. | |

| 21 | 姜伯玲.重离子辐照诱变选育纤维素酶高产菌株及其发酵工艺的研究[D].兰州:中国科学院研究生院,2016. |

| JIANG B L. Study on selection and fermentation of cellulase high-yielding strains by heavy ion irradiation mutagenesis[D]. Lanzhou:Graduate School of Chinese Academy of Sciences, 2016. | |

| 22 | 毛丽春,修立辉,胡刚.产纤维素酶细菌菌株的分离鉴定及产酶条件优化[J].中国酿造,2018,37(4):83-87. |

| MAO L C, XIU L H, HU G. Isolation and identification of cellulase-producing bacteria and optimization of their enzyme-producing conditions[J]. China Brew., 2018, 37(4): 83-87. | |

| 23 | BRUNE A. Symbiotic digestion of lignocellulose in termite guts[J]. Nat. Rev. Microbiol., 2014, 12(3): 168-180. |

| 24 | 毛婷,朱瑞清,牛永艳,等.纤维素降解芽孢菌的筛选及产酶条件优化[J].中国酿造,2020,39(1):71-76. |

| MAO T, ZHU R Q, NIU Y Y, et al.. Screening and enzyme production conditions optimization of cellulose-degrading Bacillus [J]. China Brew., 2020, 39(1): 71-76. | |

| 25 | 韦燕琪,宁思敏,韦昌浩,等. 高产纤维素酶产生菌的筛选、鉴定及发酵条件优化[J/OL]. 中国饲料,2024:1-9[2024-06-20]. . |

| WEI Y Q, NING S M, WEI C H, et al.. Screening, identification and optimization of fermentation conditions of cellulase producing bacteria[J/OL]. Chinese Feed, 2024: 1-9[2024-06-20]. . | |

| 26 | 钟斌,陶文玲,倪思毅,等. 一株纤维素降解菌的筛选、鉴定及产酶条件优化[J]. 江西农业大学学报, 2021, 43(05): 1167-1177. |

| ZHONG B, TAO W L, NI S Y, et al.. Screening, identification and optimization of enzyme production conditions of a cellulose-degrading bacterium[J]. J. Jiangxi Agric. Univ., 2021, 43 (05): 1167-1177. |

| [1] | 孔蒙蒙, 卢鹏, 陈千思, 乔学义, 陈善义, 金静静, 郑雪坳, 曹培健, 陶界锰. 产纤维素酶工程菌株的构建及其在醇化烟叶中的应用[J]. 生物技术进展, 2024, 14(2): 263-270. |

| [2] | 张立华, 王一樊, 张旭阳, 刘千盈, 高思琦, 焦健. 响应面分析法优化酶法提取红景天苷的工艺研究[J]. 生物技术进展, 2023, 13(3): 441-448. |

| [3] | 郝捷, 李选文, 张宝, 郑超, 孙志康, 季嫱, 吴娜, 吴晗, 李力群. 纤维素酶在烟草中的应用进展[J]. 生物技术进展, 2023, 13(2): 166-173. |

| [4] | 张文静, 佟晔, 杨锡文, 曹彦金, 魏计东. 高产中性蛋白酶菌株的筛选、优化及中试放大[J]. 生物技术进展, 2022, 12(1): 112-119. |

| [5] | 张清翠,石雅丽,刘安礼,胡建华,李永丽,孙亚超,何可欣,夏婷,鲍彦彬. 外切纤维素酶的研究与应用进展[J]. 生物技术进展, 2020, 10(5): 495-502. |

| [6] | 严海璘,,朱宗财,,张王斌,,杜培秀,张超,赵文军4,李为民. 梨火疫病菌两个Sec依赖的外泌纤维素酶鉴定及在侵染梨幼果过程中的基因表达分析[J]. 生物技术进展, 2020, 10(5): 517-523. |

| [7] | 李丽娟,夏文静,马贵平. 碳纳米管固定化纤维素酶的最佳工艺研究[J]. 生物技术进展, 2020, 10(4): 426-431. |

| [8] | 陈媛,李金阳,张宇宏,刘波,张志伟,徐欣欣,张伟. 一株特异腐质霉纤维素酶高产突变株的鉴定分析[J]. 生物技术进展, 2019, 9(2): 185-190. |

| [9] | 王加友,赵彭年,杨德玉,龙惊惊,周悦,王远. 一株纤维素分解菌的筛选、鉴定及其对玉米秸秆的降解效果[J]. 生物技术进展, 2018, 8(2): 132-139. |

| [10] | 刘云海,李钰,孙芳娇,高炳淼. 重组芋螺毒素His-Xa-MrVIB发酵条件优化[J]. 生物技术进展, 2016, 6(5): 352-356. |

| [11] | 韩笑,闫培生,史翠娟,杨树燕,李永鹏,邹雪平. 海洋微生物产纤维素酶及其应用研究进展[J]. 生物技术进展, 2015, 5(3): 191-195. |

| [12] | 杨煌建,张祝兰,黄小珍,郑卫. 链霉菌FIM-0916产安福霉素的发酵条件优化[J]. 生物技术进展, 2014, 4(2): 118-123. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

版权所有 © 2021《生物技术进展》编辑部