生物技术进展 ›› 2025, Vol. 15 ›› Issue (1): 93-101.DOI: 10.19586/j.2095-2341.2024.0093

收稿日期:2024-04-29

接受日期:2024-07-05

出版日期:2025-01-25

发布日期:2025-03-07

通讯作者:

张伟

作者简介:刘晓敏E-mail: 13629474732@126.com;

基金资助:

Xiaomin LIU( ), Ting LU, Yong LI, Meng WANG, Baokun ZHU, Wei ZHANG(

), Ting LU, Yong LI, Meng WANG, Baokun ZHU, Wei ZHANG( )

)

Received:2024-04-29

Accepted:2024-07-05

Online:2025-01-25

Published:2025-03-07

Contact:

Wei ZHANG

摘要:

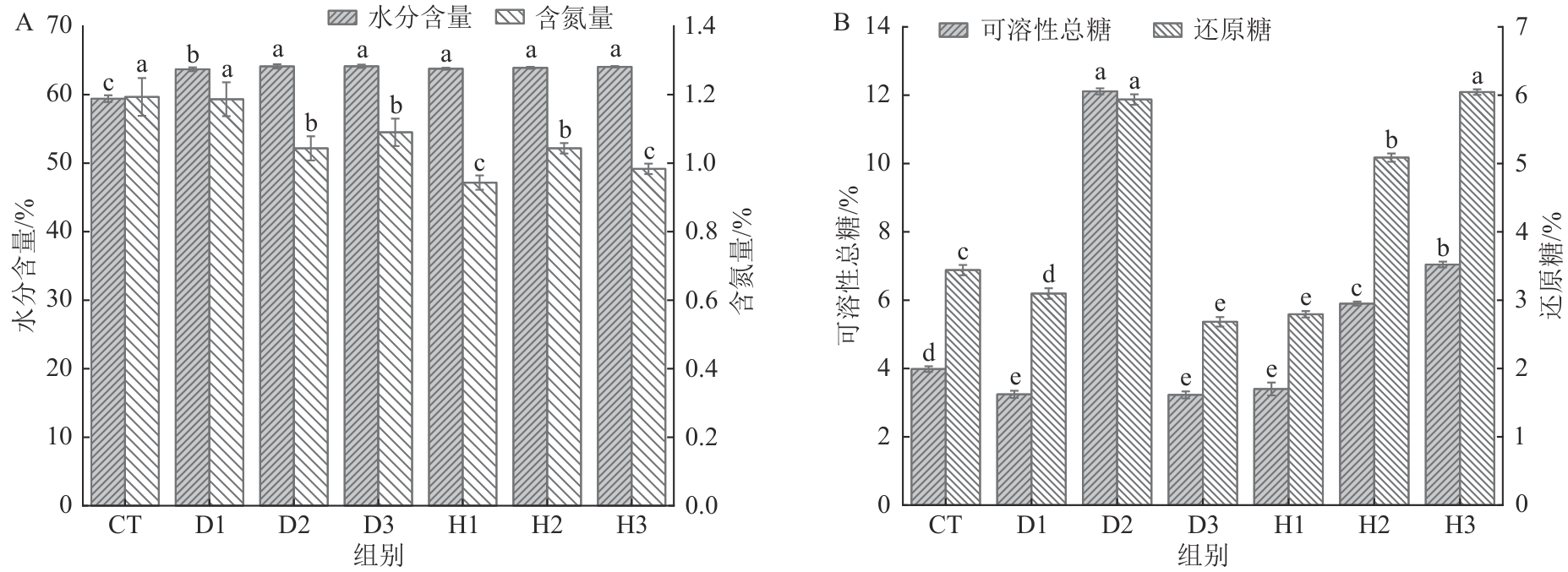

为研究不同酶制剂对发酵烟叶的影响,以云南烟叶为试验材料,采用多种酶制剂对烟叶进行酶解处理,并利用葡萄酒果酒酵母菌发酵技术,旨在制备出风味更为丰富饱满的烟叶产品。实验分析了不同酶制剂处理对烟叶常规化学成分、挥发性风味物质及感官品质的影响。结果表明,经过酶解处理,各组烟叶的水分含量和含氮量无较大变化,含氮量大致在0.98%~1.18%,其中100 U·g-1风味蛋白酶处理组烟叶中可溶性总糖和还原糖含量最高,分别为12.11%和5.93%。各组烟叶中挥发性风味物质总量均有所提升,最高为180.029 μg·g-1,而且各组烟叶中主要特征性风味物质含量也得到提升,如新植二烯、苯乙醇、茄酮和巨豆三烯酮等,各组烟叶经酶解处理后感官品质也得到提升。综合分析发现,利用70 U·g-1风味蛋白酶和50 U·g-1 α-淀粉酶复配对烟叶进行酶解处理,可以使烟叶的化学成分更协调,香气成分更充足,感官指标也更好。因此,通过酶解发酵的方式可以提升烟叶的品质,为烟叶的进一步商业化应用提供了依据。

中图分类号:

刘晓敏, 卢婷, 李勇, 王猛, 朱保昆, 张伟. 酶制剂预处理对酵母菌发酵烟叶的影响[J]. 生物技术进展, 2025, 15(1): 93-101.

Xiaomin LIU, Ting LU, Yong LI, Meng WANG, Baokun ZHU, Wei ZHANG. The Impact of Enzyme Treatment on Yeast Fermentation of Tobacco[J]. Current Biotechnology, 2025, 15(1): 93-101.

| 处理组 | 酶制剂用量/(U·g-1) | ||

|---|---|---|---|

| 脂肪酶 | 风味蛋白酶 | α-淀粉酶 | |

| CT | — | — | — |

| D1 | 100 | — | — |

| D2 | — | 100 | — |

| D3 | — | — | 100 |

| H1 | 100 | — | 50 |

| H2 | 100 | 70 | — |

| H3 | — | 70 | 50 |

表1 试验设计

Table 1 Experimental design

| 处理组 | 酶制剂用量/(U·g-1) | ||

|---|---|---|---|

| 脂肪酶 | 风味蛋白酶 | α-淀粉酶 | |

| CT | — | — | — |

| D1 | 100 | — | — |

| D2 | — | 100 | — |

| D3 | — | — | 100 |

| H1 | 100 | — | 50 |

| H2 | 100 | 70 | — |

| H3 | — | 70 | 50 |

| 指标 | 特征描述 | 分值 | 指标 | 特征描述 | 分值 |

|---|---|---|---|---|---|

| 香气质 | 好 | 7~9 | 香气量 | 充足 | 7~9 |

| 较好 | 4~6 | 尚充足 | 4~6 | ||

| 差 | 1~3 | 较少 | 1~3 | ||

| 余味 | 舒适 | 7~9 | 杂气 | 小 | 7~9 |

| 较舒适 | 4~6 | 较小 | 4~6 | ||

| 差 | 1~3 | 大 | 1~3 | ||

| 甜润感 | 显著 | 7~9 | 刺激性 | 小 | 7~9 |

| 稍显著 | 4~6 | 较小 | 4~6 | ||

| 不显著 | 1~3 | 大 | 1~3 | ||

| 燃烧性 | 好 | 7~9 | |||

| 中 | 4~6 | ||||

| 差 | 1~3 |

表2 烟叶感官评价标准

Table 2 Sensory evaluation criteria for tobacco

| 指标 | 特征描述 | 分值 | 指标 | 特征描述 | 分值 |

|---|---|---|---|---|---|

| 香气质 | 好 | 7~9 | 香气量 | 充足 | 7~9 |

| 较好 | 4~6 | 尚充足 | 4~6 | ||

| 差 | 1~3 | 较少 | 1~3 | ||

| 余味 | 舒适 | 7~9 | 杂气 | 小 | 7~9 |

| 较舒适 | 4~6 | 较小 | 4~6 | ||

| 差 | 1~3 | 大 | 1~3 | ||

| 甜润感 | 显著 | 7~9 | 刺激性 | 小 | 7~9 |

| 稍显著 | 4~6 | 较小 | 4~6 | ||

| 不显著 | 1~3 | 大 | 1~3 | ||

| 燃烧性 | 好 | 7~9 | |||

| 中 | 4~6 | ||||

| 差 | 1~3 |

图1 酶处理对烟叶常规化学成分的影响A:水分含量和含氮量;B:可溶性总糖和还原糖含量。不同小写字母表示不同酶处理组各指标间存在显著性差异。

Fig. 1 The effect of enzyme treatment on the conventional chemical composition of tobacco

| 中文名称 | CT | D1 | D2 | D3 | H1 | H2 | H3 |

|---|---|---|---|---|---|---|---|

| 3-甲基-1-丁醇 | 0.240±0.013g | 0.564±0.006e | 0.617±0.001d | 0.670±0.016c | 0.479±0.001f | 0.810±0.006b | 0.885±0.007a |

| 芳樟醇 | 0.146±0.008b | 0.215±0.007a | 0.126±0.006c | 0.148±0.004b | 0.146±0.001b | 0.158±0.011b | 0.215±0.007a |

| 植物醇 | 0.123±0.004a | 0.092±0.000b | 0.000±0.000c | 0.093±0.004b | 0.000±0.000c | 0.000±0.000c | 0.000±0.000c |

| 香叶醇 | 0.102±0.003a | 0.084±0.006bc | 0.066±0.001d | 0.092±0.003ab | 0.063±0.004d | 0.072±0.014cd | 0.085±0.001bc |

| 苯乙醇 | 17.718±0.308d | 19.014±0.348bc | 18.692±0.235c | 20.386±0.317a | 19.424±0.034b | 18.758±0.147c | 20.348±0.252a |

| 3-氧代-α-紫罗兰醇 | 0.570±0.014f | 1.009±0.006a | 0.966±0.001b | 0.932±0.014c | 0.718±0.011d | 0.688±0.006e | 0.000±0.000g |

| 苯乙酸乙酯 | 0.843±0.003b | 0.736±0.000d | 0.751±0.010cd | 0.830±0.007b | 0.770±0.013c | 0.640±0.016e | 0.876±0.001a |

| β-丁酸苯乙酯 | 1.857±0.010f | 1.991±0.001d | 1.974±0.006e | 2.396±0.008a | 2.086±0.000c | 1.653±0.004g | 2.354±0.006b |

| 十六烷酸甲酯 | 0.349±0.001g | 0.801±0.006a | 0.701±0.001b | 0.678±0.011c | 0.660±0.000d | 0.540±0.014f | 0.611±0.003e |

| 十六烷酸乙酯 | 0.440±0.008g | 1.134±0.001b | 0.939±0.010e | 1.154±0.004a | 0.978±0.001d | 0.533±0.004f | 1.060±0.000c |

| (E)-9-十八碳烯酸乙酯 | 0.000±0.000c | 0.035±0.007ab | 0.038±0.004a | 0.029±0.013ab | 0.034±0.006ab | 0.023±0.001ab | 0.037±0.003ab |

| 亚油酸甲酯 | 0.031±0.006d | 0.068±0.008a | 0.053±0.001b | 0.056±0.008ab | 0.050±0.001bc | 0.038±0.006cd | 0.052±0.003b |

| 丙酮 | 4.118±0.150a | 3.183±0.046c | 3.232±0.020b | 3.121±0.030c | 3.759±0.270b | 2.969±0.141c | 3.837±0.055ab |

| 2-壬酮 | 0.022±0.000c | 0.030±0.003bc | 0.032±0.006bc | 0.058±0.011a | 0.035±0.007bc | 0.038±0.003b | 0.053±0.004a |

| 茄酮 | 3.873±0.004bc | 4.784±0.263a | 3.549±0.041c | 4.816±0.250a | 4.180±0.113b | 3.585±0.062c | 4.831±0.216a |

| 2-哌啶酮 | 0.243±0.004e | 0.326±0.001a | 0.315±0.007b | 0.324±0.006a | 0.268±0.003d | 0.244±0.001e | 0.297±0.003c |

| 巨豆三烯酮 | 3.911±0.074c | 5.021±0.049a | 3.852±0.107cd | 5.091±0.168a | 4.361±0.148b | 3.673±0.004d | 4.901±0.058a |

| 3-羟基-β-大马士革酮 | 0.077±0.010b | 0.152±0.003a | 0.090±0.014b | 0.142±0.001a | 0.088±0.000b | 0.077±0.004b | 0.092±0.003b |

| 壬醛 | 0.072±0.000c | 0.031±0.001e | 0.043±0.004d | 0.081±0.003b | 0.040±0.007d | 0.131±0.001a | 0.038±0.004de |

| 苯乙醛 | 0.408±0.011a | 0.272±0.003c | 0.229±0.008e | 0.189±0.001g | 0.359±0.004b | 0.204±0.006f | 0.246±0.001d |

| 己酸 | 0.000±0.000d | 1.195±0.007a | 1.098±0.049b | 0.000±0.000d | 0.887±0.010c | 0.000±0.000d | 1.070±0.001b |

| 3-甲基戊酸 | 0.982±0.020d | 1.812±0.017c | 1.674±0.148b | 1.233±0.028c | 0.931±0.024d | 1.909±0.013a | 1.901±0.074a |

| 异巴豆酸 | 0.162±0.003a | 0.140±0.014b | 0.094±0.001c | 0.141±0.013b | 0.133±0.005b | 0.111±0.000c | 0.112±0.011c |

| 烟碱 | 33.080±0.163e | 41.893±0.858b | 37.203±0.434d | 43.935±0.550a | 36.456±0.198d | 32.556±0.126f | 39.178±0.049c |

| 二烯烟碱 | 0.974±0.006c | 1.094±0.001b | 0.964±0.006c | 1.260±0.014a | 0.000±0.000d | 0.000±0.000d | 0.000±0.000d |

| 新植二烯 | 48.761±1.121e | 72.900±0.375a | 54.087±0.553d | 73.923±0.502a | 60.884±1.075c | 47.359±0.014e | 66.289±0.151b |

| 2-甲氧基-4-乙烯基苯酚 | 0.449±0.001g | 0.727±0.002b | 0.644±0.006d | 0.812±0.003a | 0.669±0.003c | 0.519±0.005f | 0.632±0.003e |

表3 酶处理发酵后烟叶中主要挥发性物质的含量 (μg·g-1)

Table 3 The content of major volatile compounds in tobacco after enzyme treatment and fermentation

| 中文名称 | CT | D1 | D2 | D3 | H1 | H2 | H3 |

|---|---|---|---|---|---|---|---|

| 3-甲基-1-丁醇 | 0.240±0.013g | 0.564±0.006e | 0.617±0.001d | 0.670±0.016c | 0.479±0.001f | 0.810±0.006b | 0.885±0.007a |

| 芳樟醇 | 0.146±0.008b | 0.215±0.007a | 0.126±0.006c | 0.148±0.004b | 0.146±0.001b | 0.158±0.011b | 0.215±0.007a |

| 植物醇 | 0.123±0.004a | 0.092±0.000b | 0.000±0.000c | 0.093±0.004b | 0.000±0.000c | 0.000±0.000c | 0.000±0.000c |

| 香叶醇 | 0.102±0.003a | 0.084±0.006bc | 0.066±0.001d | 0.092±0.003ab | 0.063±0.004d | 0.072±0.014cd | 0.085±0.001bc |

| 苯乙醇 | 17.718±0.308d | 19.014±0.348bc | 18.692±0.235c | 20.386±0.317a | 19.424±0.034b | 18.758±0.147c | 20.348±0.252a |

| 3-氧代-α-紫罗兰醇 | 0.570±0.014f | 1.009±0.006a | 0.966±0.001b | 0.932±0.014c | 0.718±0.011d | 0.688±0.006e | 0.000±0.000g |

| 苯乙酸乙酯 | 0.843±0.003b | 0.736±0.000d | 0.751±0.010cd | 0.830±0.007b | 0.770±0.013c | 0.640±0.016e | 0.876±0.001a |

| β-丁酸苯乙酯 | 1.857±0.010f | 1.991±0.001d | 1.974±0.006e | 2.396±0.008a | 2.086±0.000c | 1.653±0.004g | 2.354±0.006b |

| 十六烷酸甲酯 | 0.349±0.001g | 0.801±0.006a | 0.701±0.001b | 0.678±0.011c | 0.660±0.000d | 0.540±0.014f | 0.611±0.003e |

| 十六烷酸乙酯 | 0.440±0.008g | 1.134±0.001b | 0.939±0.010e | 1.154±0.004a | 0.978±0.001d | 0.533±0.004f | 1.060±0.000c |

| (E)-9-十八碳烯酸乙酯 | 0.000±0.000c | 0.035±0.007ab | 0.038±0.004a | 0.029±0.013ab | 0.034±0.006ab | 0.023±0.001ab | 0.037±0.003ab |

| 亚油酸甲酯 | 0.031±0.006d | 0.068±0.008a | 0.053±0.001b | 0.056±0.008ab | 0.050±0.001bc | 0.038±0.006cd | 0.052±0.003b |

| 丙酮 | 4.118±0.150a | 3.183±0.046c | 3.232±0.020b | 3.121±0.030c | 3.759±0.270b | 2.969±0.141c | 3.837±0.055ab |

| 2-壬酮 | 0.022±0.000c | 0.030±0.003bc | 0.032±0.006bc | 0.058±0.011a | 0.035±0.007bc | 0.038±0.003b | 0.053±0.004a |

| 茄酮 | 3.873±0.004bc | 4.784±0.263a | 3.549±0.041c | 4.816±0.250a | 4.180±0.113b | 3.585±0.062c | 4.831±0.216a |

| 2-哌啶酮 | 0.243±0.004e | 0.326±0.001a | 0.315±0.007b | 0.324±0.006a | 0.268±0.003d | 0.244±0.001e | 0.297±0.003c |

| 巨豆三烯酮 | 3.911±0.074c | 5.021±0.049a | 3.852±0.107cd | 5.091±0.168a | 4.361±0.148b | 3.673±0.004d | 4.901±0.058a |

| 3-羟基-β-大马士革酮 | 0.077±0.010b | 0.152±0.003a | 0.090±0.014b | 0.142±0.001a | 0.088±0.000b | 0.077±0.004b | 0.092±0.003b |

| 壬醛 | 0.072±0.000c | 0.031±0.001e | 0.043±0.004d | 0.081±0.003b | 0.040±0.007d | 0.131±0.001a | 0.038±0.004de |

| 苯乙醛 | 0.408±0.011a | 0.272±0.003c | 0.229±0.008e | 0.189±0.001g | 0.359±0.004b | 0.204±0.006f | 0.246±0.001d |

| 己酸 | 0.000±0.000d | 1.195±0.007a | 1.098±0.049b | 0.000±0.000d | 0.887±0.010c | 0.000±0.000d | 1.070±0.001b |

| 3-甲基戊酸 | 0.982±0.020d | 1.812±0.017c | 1.674±0.148b | 1.233±0.028c | 0.931±0.024d | 1.909±0.013a | 1.901±0.074a |

| 异巴豆酸 | 0.162±0.003a | 0.140±0.014b | 0.094±0.001c | 0.141±0.013b | 0.133±0.005b | 0.111±0.000c | 0.112±0.011c |

| 烟碱 | 33.080±0.163e | 41.893±0.858b | 37.203±0.434d | 43.935±0.550a | 36.456±0.198d | 32.556±0.126f | 39.178±0.049c |

| 二烯烟碱 | 0.974±0.006c | 1.094±0.001b | 0.964±0.006c | 1.260±0.014a | 0.000±0.000d | 0.000±0.000d | 0.000±0.000d |

| 新植二烯 | 48.761±1.121e | 72.900±0.375a | 54.087±0.553d | 73.923±0.502a | 60.884±1.075c | 47.359±0.014e | 66.289±0.151b |

| 2-甲氧基-4-乙烯基苯酚 | 0.449±0.001g | 0.727±0.002b | 0.644±0.006d | 0.812±0.003a | 0.669±0.003c | 0.519±0.005f | 0.632±0.003e |

| 1 | 郝捷,李选文,张宝,等.纤维素酶在烟草中的应用进展[J].生物技术进展,2023,13(2):166-173. |

| HAO J, LI X W, ZHANG B, et al.. Application progress of cellulase in tobacco[J]. Curr. Biotechnol., 2023, 13(2): 166-173. | |

| 2 | 褚继登,顾毓敏,蔡宪杰 等.文山初烤烟叶主要理化指标与感官评吸质量的关系分析[J].东北农业科学,2022,47(2):150-155. |

| CHU J, GU Y M, CAI X J,et al.. Analysis on the relationship between main physical and chemical indexes and sensory smoking quality of primary flue-cured tobacco in wenshan[J]. J. Northeast Agric. Sci., 2022, 47(2): 50-155. | |

| 3 | 蔡宪杰,刘茂林,谢德平,等.提高上部烟叶工业可用性技术研究[J].烟草科技,2010,43(6):10-17. |

| CAI X J, LIU M L, XIE D P, et al.. Study on improving usability of upper flue-cured tobacco leaves[J]. Tob. Sci. Technol., 2010, 43(6): 10-17. | |

| 4 | 孙福艳,杨雪鹏,杨成,等.烟草增香生物技术研究进展[J].云南化工,2023,50(2):9-14. |

| SUN F Y, YANG X P, YANG C, et al.. Research progress of tobacco aroma enhancing biotechnology[J]. Yunnan Chem. Technol., 2023, 50(2): 9-14. | |

| 5 | 赵铭钦,李芳芳.微生物和酶学技术在烟草发酵中的应用及展望[J].中国农学通报,2007,23(1):314-318. |

| ZHAO M Q, LI F F. The application and prospect of the technology of microbe and enzyme during tobacco leaf fermentation[J]. Chin. Agric. Sci. Bull., 2007, 23(1): 314-318. | |

| 6 | 帅瑶,陶菡,田运霞,等.复合菌种发酵烟叶产酶及挥发性风味物质变化[J].河南农业科学,2020,49(10):162-175. |

| SHUAI Y, TAO H, TIAN Y X, et al.. Changes of enzyme production and volatile flavor compounds in tobacco leaves fermented by mixed starter[J]. J. Henan Agric. Sci., 2020, 49(10): 162-175. | |

| 7 | 郝捷,季嫱,李力群,等.生物酶和微生物技术改善烟叶香气的研究进展[J].生物技术进展,2022,12(6):817-824. |

| HAO J, JI Q, LI L Q, et al.. Research progress on improving aroma of tobacco leaf with bio-enzymes and microorganism technology[J]. Curr. Biotechnol., 2022, 12(6): 817-824. | |

| 8 | 蔡文,吴鑫颖,张倩颖 等.高斯芽孢杆菌产中性蛋白酶条件优化及其对烟叶发酵的影响[J].食品与发酵科技,2022,58(3):92-98, 118. |

| CAI W, WU X Y, ZHANG Q Y,et al. Optimization of neutral protease production by Bacillus kochii and its effect on fermentation of tobacco leaf[J]. Food Ferment. Sci. Technol., 2022, 58(3): 92-98, 118. | |

| 9 | 刘方玉,高强,付沙,等.雪茄烟叶发酵工艺及其微生物技术研究进展[J].安徽农业科学,2023,51(14):18-21, 24. |

| LIU F Y, GAO Q, FU S, et al.. Research progress on fermentation technology and microbial technology of cigar tobacco leaves[J]. J. Anhui Agric. Sci., 2023, 51(14): 18-21, 24. | |

| 10 | 肖明礼,杨庆,林锐峰,等.风味蛋白酶提升烟叶抽吸品质的研究[J].浙江农业学报,2014,26(1):181-185. |

| XIAO M L, YANG Q, LIN R F, et al. Research on flavour protease to enhance smoking quality of tobacco[J]. Acta Agri. Zhejiangensis,2014,26(1):181-185. | |

| 11 | 孙伟峰,周志磊,殷春燕,等.酶解细胞壁对低等级烟叶品质的改良作用[J].西北农林科技大学学报(自然科学版),2014,42(7):70-76. |

| SUN W F, ZHOU Z L, YIN C Y, et al.. Enzymatic degradation of cell wall substances to improve quality of low-grade tobacco[J]. J. Northwest A F Univ. Nat. Sci. Ed., 2014, 42(7): 70-76. | |

| 12 | 琚绍煊,时向东,王骏,等.外源复合酶制剂对发酵后茄芯烟叶品质的影响[J].山东农业科学,2023,55(6):69-76. |

| JU S X, SHI X D, WANG J, et al.. Effect of exogenous complex enzyme preparation on quality of filler tobacco leaves after fermentation[J]. Shandong Agric. Sci., 2023, 55(6): 69-76. | |

| 13 | 郑勤安.造纸法再造烟叶生产过程中微生物增质剂的应用研究[J].浙江工业大学学报,2004,32(4):442-446+458. |

| ZHENG Q A. Study of the application of microorganism quality-Enhancer in manufacturing tobacco slice by papermaking process[J]. J. Zhejiang Univ. Technol., 2004, 32(4): 442-446+458. | |

| 14 | 肖琳,苟中军,邹滢,等.酶解与发酵工艺改善黄油风味的研究[J].食品与发酵科技,2023,59(5):71-75+103. |

| XIAO L, GOU Z J, ZOU Y, et al.. Study on the application of enzymatic hydrolysis and fermentation technology in improving the flavor of butter[J]. Food Ferment. Sci. Technol., 2023, 59(5): 71-75+103. | |

| 15 | 国家烟草专卖局. 烟草及烟草制品试样的制备和水分测定烘箱法: [S].北京:中国标准出版社,1996. |

| 16 | 王瑞新.烟草化学品质分析法[M].郑州:河南科学技术出版社,1990. |

| 17 | 王瑞新.烟草化学[M].北京:中国农业出版社,2003. |

| 18 | 朱春晖,索卫国,黄卫东,等.烟草及烟草制品中总氮测定方法研究进展[J].农业与技术,2020,40(2):16-18. |

| ZHU C H, SUO W G, HUANG W D, et al.. Research progress on determination methods of total nitrogen in tobacco and tobacco products[J]. Agric. Technol., 2020, 40(2): 16-18. | |

| 19 | 倪伟,陈开波,徐志强 等.使用GC/MS和GC-O鉴定皖南烟叶主要呈香组分[J].食品与生物技术学报,2019,38(6):137-143. |

| NI W, CHEN K B, XU Z Q,et al.. Identification of main aroma compounds in tobacco leaves from southern anhui using GC/MS and GC-O[J]. J. Food Sci. Biotechnol., 2019, 38(6): 137-143. | |

| 20 | 包勤,张艳玲,王爱国,等.2002—2013年间我国烤烟主要化学成分变化趋势及原因分析[J].烟草科技,2015,48(7):14-19. |

| BAO Q, ZHANG Y L, WANG A G, et al.. Variation of main chemical components in flue-cured tobacco leaves in China during 2002-2013 and causal analysis[J]. Tob. Sci. Technol., 2015, 48(7): 14-19. | |

| 21 | 樊文举,高娟娟,张建新.外源酶制剂对烤烟烟叶化学品质的影响[J].福建农业学报,2017,32(6):652-659. |

| FAN W J, GAO J J, ZHANG J X. Effect of enzyme treatment on chemical quality of flue-cured tobacco leaves[J]. Fujian J. Agric. Sci., 2017, 32(6): 652-659. | |

| 22 | 许春平,杨琛琛,王铮 等.复合生物酶液处理低次烟叶制备烟用香料[J].郑州轻工业学院学报(自然科学版),2014,29(2):23-26. |

| XU C P, YANG C C, WANG Z,et al.. The preparation of tobacco flavor from discarded tobacco leaf by multi-bioenzyme[J]. J. Zhengzhou Univ. Light Ind. Nat. Sci. Edit., 2014, 29(2): 23-26. | |

| 23 | 黄贺敏,吴丽香,邓梅忠,等.不同品质烟叶微生物群落与其挥发性成分的关联研究[J].食品与生物技术学报,2022,41(12):85-95. |

| HUANG H M, WU L X, DENG M Z, et al.. Study on the correlation between microbial communities and volatile aroma compounds in tobacco leaves of different qualities[J]. J. Food Sci. Biotechnol., 2022, 41(12): 85-95. | |

| 24 | 胡婉蓉,蔡文,郑召君,等.发酵介质和发酵过程对雪茄烟叶品质的影响[J].烟草科技,2023,56(2):41-52. |

| HU W R, CAI W, ZHENG Z J, et al.. Effects of fermentation media and processes on cigar tobacco quality[J]. Tob. Sci. Technol., 2023, 56(2): 41-52. | |

| 25 | 张锐新,苏谦,杨昌鹤,等.堆积发酵时间对五指山茄衣烟叶品质的影响[J].山东农业科学,2020,52(4):57-61. |

| ZHANG R X, SU Q, YANG C H, et al.. Effect of stacking fermentation time on quality of Wuzhishan cigar wrapper tobacco leaves[J]. Shandong Agric. Sci., 2020, 52(4): 57-61. | |

| 26 | 陈德鑫,许家来,马志远,等.一株新的具有高效降低烟碱含量的短小芽孢杆菌MK21的分离筛选及作用研究[J].中国烟草学报,2013,19(1):60-64. |

| CHEN D X, XU J L, MA Z Y, et al.. Isolation and screening of a new Brevibacillus brevis strain MK21 with high nicotine degradation effect[J]. Acta Tabac. Sin., 2013, 19(1): 60-64. | |

| 27 | 时向东,王旭锋,林开创,等.雪茄外包皮烟堆积发酵中主要中性香气物质的变化[J].西北农业学报,2013,22(7):114-119. |

| SHI X D, WANG X F, LIN K C, et al.. Changes of aroma substances in cigar wrapper tobacco leaves during the stacking fermentation[J]. Acta Agric. Boreali Occidentalis Sin., 2013, 22(7): 114-119. | |

| 28 | 方嵩,韩磊,马刚.3-氧代-α-紫罗兰醇的合成研究[J].广州化工,2013,41(10):115-117. |

| FANG S, HAN L, MA G. Study of 3-oxo-α-ionol synthesis[J]. Guangzhou Chem. Ind., 2013, 41(10): 115-117. | |

| 29 | 张希,邓宝安,张凤侠,等.不同产区烤烟烟叶中性致香物质的对比分析[J].轻工科技,2023,39(4):31-34, 41. |

| ZHANG X, DENG B A, ZHANG F X, et al. Comparative analysis of neutral volatile compounds in flue-cured tobacco leaves from different regions of production[J]. Light Ind. Sci. Technol., 2023, 39(4), 31-34, 41. | |

| 30 | 李佳颖,马君红,李志鹏,等.烤烟茄酮含量与化学成分和感官质量的关系[J].河南农业科学,2016,45(12):34-39. |

| LI J Y, MA J H, LI Z P, et al.. Relationship between solanone content and chemical constituent, sensory quality of flue-cured tobacco[J]. J. Henan Agric. Sci., 2016, 45(12): 34-39. | |

| 31 | SLAGHENAUFI D, M-CPERELLO, MARCHAND S, et al.. Quantification of megastigmatrienone, a potential contributor to tobacco aroma in spirits[J]. Food Chem., 2016, 203: 41-48. |

| 32 | 李红涛,赵志伟,王勇,等.烟用香精3-甲基戊酸薄荷酯的合成及分析[J].安徽农业科学,2013,41(28):11509-11511. |

| LI H T, ZHAO Z W, WANG Y, et al.. Synthesis and analysis of cigarette pennyroyal essence menthyl (3-methyl) pentanoate[J]. J. Anhui Agric. Sci., 2013, 41(28): 11509-11511. |

| [1] | 孔蒙蒙, 卢鹏, 陈千思, 乔学义, 陈善义, 金静静, 郑雪坳, 曹培健, 陶界锰. 产纤维素酶工程菌株的构建及其在醇化烟叶中的应用[J]. 生物技术进展, 2024, 14(2): 263-270. |

| [2] | 赛子林, 齐虹凌, 李云, 王玉, 耿一超. 生物炭对植烟土壤养分及烤烟产质量的影响[J]. 生物技术进展, 2024, 14(2): 271-277. |

| [3] | 郝捷, 李选文, 张宝, 郑超, 孙志康, 季嫱, 吴娜, 吴晗, 李力群. 纤维素酶在烟草中的应用进展[J]. 生物技术进展, 2023, 13(2): 166-173. |

| [4] | 王林,朱金峰,许自成,张景华. 不同酶制剂对烤烟上部叶化学成分、游离态和糖苷结合态中性香气成分的影响[J]. 生物技术进展, 2015, 5(6): 455-460. |

| [5] | 蓝江林, 刘波, 宋泽琼, 史怀, 黄素芳. 微生物发酵床养猪技术研究进展[J]. 生物技术进展, 2012, 2(6): 411-416. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

版权所有 © 2021《生物技术进展》编辑部