生物技术进展 ›› 2024, Vol. 14 ›› Issue (6): 957-966.DOI: 10.19586/j.2095-2341.2024.0101

李文( ), 陈万超, 吴迪, 张忠, 刘朋, 李正鹏, 杨焱(

), 陈万超, 吴迪, 张忠, 刘朋, 李正鹏, 杨焱( )

)

收稿日期:2024-05-15

接受日期:2024-07-02

出版日期:2024-11-25

发布日期:2024-12-27

通讯作者:

李文,杨焱

作者简介:李文 E-mail:liwen3848@126.com;基金资助:

Wen LI( ), Wanchao CHEN, Di WU, Zhong ZHANG, Peng LIU, Zhengpeng LI, Yan YANG(

), Wanchao CHEN, Di WU, Zhong ZHANG, Peng LIU, Zhengpeng LI, Yan YANG( )

)

Received:2024-05-15

Accepted:2024-07-02

Online:2024-11-25

Published:2024-12-27

Contact:

Wen LI,Yan YANG

摘要:

为筛选适用于大球盖菇采后品质提升的干制技术,探究了热泵干制和射频干制技术对大球盖菇风味成分含量及品质的影响。不同干制技术对大球盖菇样品风味成分含量及品质影响较大。脂质、烷烃、杂环类物质是射频干制的大球盖菇样品中的主要挥发性化合物,醛酮醇类物质是热泵干制的大球盖菇样品中的主要挥发性化合物,挥发性成分主要富集在初级醇类、酮类、杂芳香族化合物的合成代谢通路上。甜味、鲜味氨基酸是两种干制样品中的主要氨基酸种类,其中,谷氨酸、丝氨酸、丙氨酸和缬氨酸等是主要氨基酸;热泵干制样品中滋味成分核苷酸、氨基酸、有机酸总量及等鲜浓度值均高于射频干制样品。热泵干制样品鲜甜味滋味成分的电子舌及挥发性硫化物和芳香族化合物的电子鼻响应信号更高。大球盖菇干品的风味成分、感官及质构分析结果显示,热泵干制技术更有利于大球盖菇干品形成愉悦风味和较好品质外观,该技术有望进一步推广应用于大球盖菇采后品质提升。

中图分类号:

李文, 陈万超, 吴迪, 张忠, 刘朋, 李正鹏, 杨焱. 热泵干制和射频干制对大球盖菇风味成分及品质的影响[J]. 生物技术进展, 2024, 14(6): 957-966.

Wen LI, Wanchao CHEN, Di WU, Zhong ZHANG, Peng LIU, Zhengpeng LI, Yan YANG. Effects of Heat Pump Drying and Radio Frequency Drying on Flavor Components and Quality of Stropharia rugosoannulata Mushroom[J]. Current Biotechnology, 2024, 14(6): 957-966.

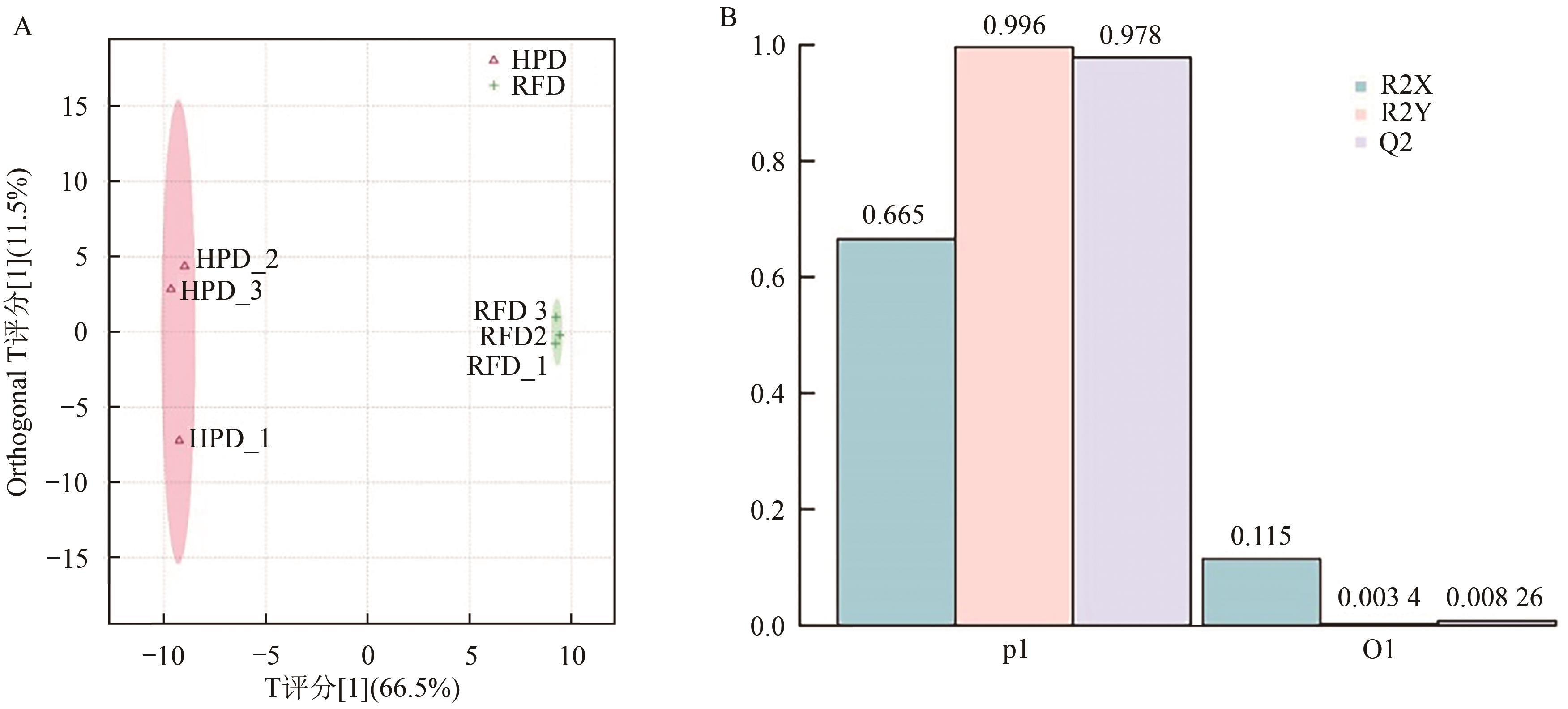

图2 大球盖菇热泵干制和射频干制样品OPLS-DA分析A:样本组分布图;B:模型参数图。OPLS-DA分析图中样本编号表示3组重复测试样本。

Fig. 2 OPLS-DA analysis of heat pump drying and radio frequency drying samples of S. rugosoannulata mushrooms

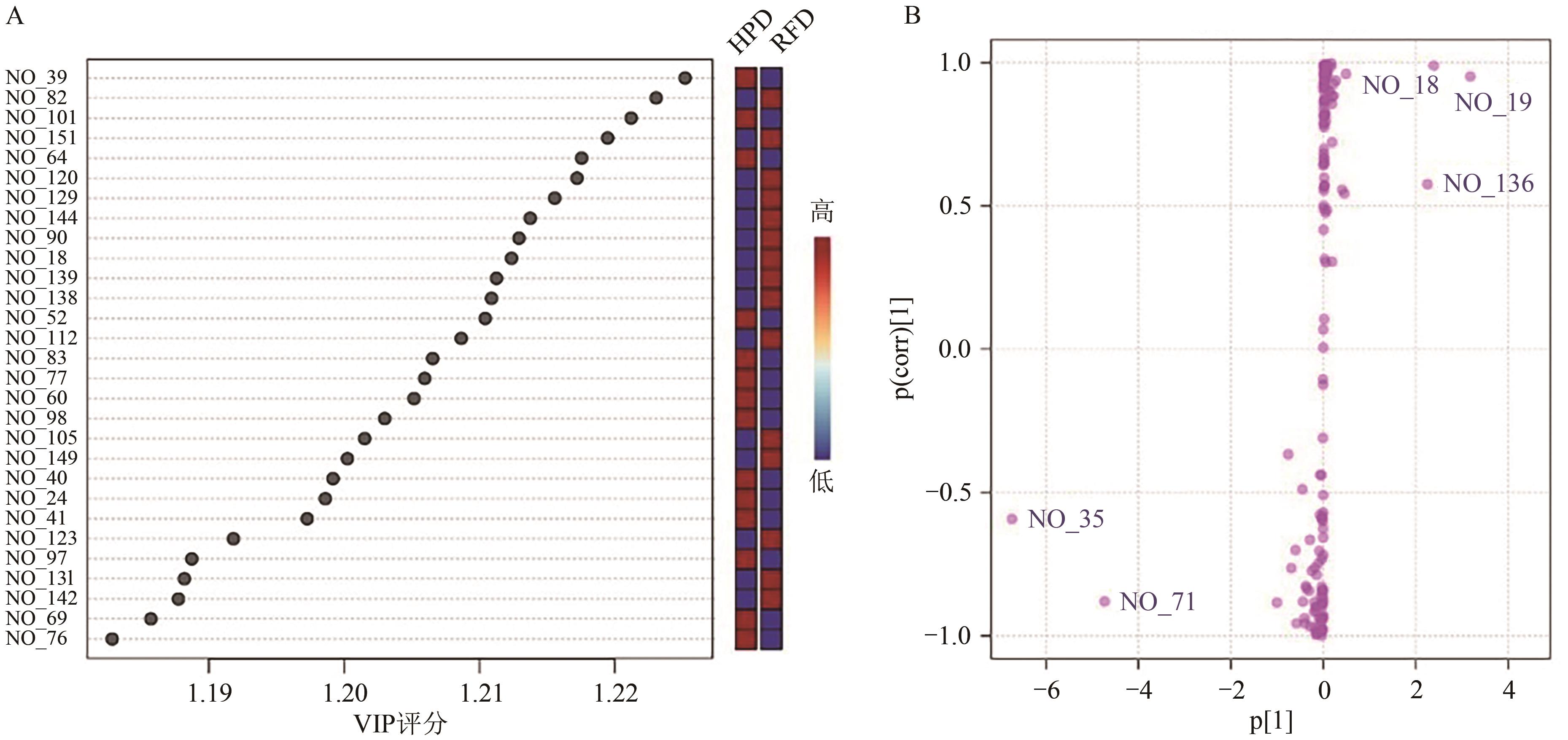

图3 大球盖菇热泵干制和射频干制样品差异代谢物分析A:主要差异代谢物在样本组中的权重值和分布图;B:引起组间差异的差异代谢物Splot载荷图。

Fig. 3 Differential metabolite analysis of heat pump drying and radio frequency drying samples of S. rugosoannulata mushrooms

| 代谢物编号 | 代谢物名称 | CAS号 | 分子式 |

|---|---|---|---|

| NO_18* | 2-甲基丁醛 | 96-17-3 | C5H10O |

| NO_19* | 3-甲基丁醛 | 590-86-3 | C5H10O |

| NO_24 | 正丁醚 | 142-96-1 | C8H18O |

| NO_35* | 正己醛 | 66-25-1 | C6H12O |

| NO_39 | 乙基苯 | 100-41-4 | C8H10 |

| NO_40 | 1,3-二甲基苯 | 108-38-3 | C8H10 |

| NO_41 | 5-甲基己醛 | 1860-39-5 | C7H14O |

| NO_52 | 苯乙烯 | 100-42-5 | C8H8 |

| NO_60 | (E)-2-庚烯醛 | 18829-55-5 | C7H12O |

| NO_64 | 十二甲基环己硅氧烷 | 540-97-6 | C12H36O6Si6 |

| NO_69 | 壬醛 | 124-19-6 | C9H18O |

| NO_71* | 1-辛烯-3-醇 | 3391-86-4 | C8H16O |

| NO_76 | 吡咯 | 109-97-7 | C4H5N |

| NO_77 | 十二甲基五硅氧烷 | 141-63-9 | C12H36O4Si5 |

| NO_82 | 3-乙基-5-甲基-1-丙基环己烷 | 549940 | C12H24 |

| NO_83 | 2-十一酮 | 112-12-9 | C11H22O |

| NO_90 | 2(5H)-呋喃酮 | 497-23-4 | C4H4O2 |

| NO_97 | 苯乙醇 | 60-12-8 | C8H10O |

| NO_98 | N-甲基胞嘧啶 | 486-86-2 | C12H16N2O |

| NO_101 | 邻苯二甲酸二丁酯 | 84-74-2 | C16H22O4 |

| NO_105 | 丙醛 | 123-38-6 | C3H6O |

| NO_112 | 2-甲基戊醛 | 123-15-9 | C6H12O |

| NO_120 | 乙酰戊基 | 96-04-8 | C7H12O2 |

| NO_123 | 2,6-二甲基-3-庚酮 | 19549-83-8 | C9H18O |

| NO_129 | 2,3-壬二酮 | 57644-90-3 | C9H16O2 |

| NO_131 | 6-氨基脲嘧啶 | 873-83-6 | C4H5N3O2 |

| NO_136* | 四甲基吡嗪 | 1124-11-4 | C8H12N2 |

| NO_138 | 1-乙基-1H-吡咯-2-甲醛 | 2167-14-8 | C7H9NO |

| NO_139 | 2-甲氧基乙醇 | 109-86-4 | C3H8O2 |

| NO_142 | 3-苯基呋喃 | 13679-41-9 | C10H8O |

| NO_144 | 亚乙基苯乙醛 | 4411-89-6 | C10H10O |

| NO_149 | 十二甲基五硅氧烷 | 141-63-9 | C12H36O4Si5 |

| NO_151 | 十六烷酸甲酯 | 112-39-0 | C17H34O2 |

表1 大球盖菇样本比较组间差异代谢物信息

Table 1 Differential metabolite information between comparative sample groups of S. rugosoannulata mushrooms

| 代谢物编号 | 代谢物名称 | CAS号 | 分子式 |

|---|---|---|---|

| NO_18* | 2-甲基丁醛 | 96-17-3 | C5H10O |

| NO_19* | 3-甲基丁醛 | 590-86-3 | C5H10O |

| NO_24 | 正丁醚 | 142-96-1 | C8H18O |

| NO_35* | 正己醛 | 66-25-1 | C6H12O |

| NO_39 | 乙基苯 | 100-41-4 | C8H10 |

| NO_40 | 1,3-二甲基苯 | 108-38-3 | C8H10 |

| NO_41 | 5-甲基己醛 | 1860-39-5 | C7H14O |

| NO_52 | 苯乙烯 | 100-42-5 | C8H8 |

| NO_60 | (E)-2-庚烯醛 | 18829-55-5 | C7H12O |

| NO_64 | 十二甲基环己硅氧烷 | 540-97-6 | C12H36O6Si6 |

| NO_69 | 壬醛 | 124-19-6 | C9H18O |

| NO_71* | 1-辛烯-3-醇 | 3391-86-4 | C8H16O |

| NO_76 | 吡咯 | 109-97-7 | C4H5N |

| NO_77 | 十二甲基五硅氧烷 | 141-63-9 | C12H36O4Si5 |

| NO_82 | 3-乙基-5-甲基-1-丙基环己烷 | 549940 | C12H24 |

| NO_83 | 2-十一酮 | 112-12-9 | C11H22O |

| NO_90 | 2(5H)-呋喃酮 | 497-23-4 | C4H4O2 |

| NO_97 | 苯乙醇 | 60-12-8 | C8H10O |

| NO_98 | N-甲基胞嘧啶 | 486-86-2 | C12H16N2O |

| NO_101 | 邻苯二甲酸二丁酯 | 84-74-2 | C16H22O4 |

| NO_105 | 丙醛 | 123-38-6 | C3H6O |

| NO_112 | 2-甲基戊醛 | 123-15-9 | C6H12O |

| NO_120 | 乙酰戊基 | 96-04-8 | C7H12O2 |

| NO_123 | 2,6-二甲基-3-庚酮 | 19549-83-8 | C9H18O |

| NO_129 | 2,3-壬二酮 | 57644-90-3 | C9H16O2 |

| NO_131 | 6-氨基脲嘧啶 | 873-83-6 | C4H5N3O2 |

| NO_136* | 四甲基吡嗪 | 1124-11-4 | C8H12N2 |

| NO_138 | 1-乙基-1H-吡咯-2-甲醛 | 2167-14-8 | C7H9NO |

| NO_139 | 2-甲氧基乙醇 | 109-86-4 | C3H8O2 |

| NO_142 | 3-苯基呋喃 | 13679-41-9 | C10H8O |

| NO_144 | 亚乙基苯乙醛 | 4411-89-6 | C10H10O |

| NO_149 | 十二甲基五硅氧烷 | 141-63-9 | C12H36O4Si5 |

| NO_151 | 十六烷酸甲酯 | 112-39-0 | C17H34O2 |

| 滋味成分类别 | 滋味成分 | 含量/(mg·g-1干重) | 滋味特征 | |

|---|---|---|---|---|

| HPD | RFD | |||

| 氨基酸 | 天冬氨酸 | 0.65±0.01h | 1.88±0.12h | 甜味、鲜味 |

| 谷氨酸 | 25.23±0.80a | 23.67±2.84a | 鲜味 | |

| 苏氨酸a | 8.93±0.59d | 6.61±0.17d | 甜味 | |

| 丝氨酸 | 23.76±2.36a | 15.58±0.59b | 甜味 | |

| 甘氨酸 | 4.80±0.62f | 4.12±0.21f | 甜味 | |

| 丙氨酸 | 14.42±0.24b | 14.09±0.90b | 甜味 | |

| 脯氨酸 | 4.89±0.68f | 5.79±0.37e | 甜味 | |

| 缬氨酸a | 12.29±0.31c | 10.78±1.29c | 甜味、苦味 | |

| 甲硫氨酸a | 0.62±0.04h | 0.31±0.08k | 甜味、苦味 | |

| 异亮氨酸a | 6.61±0.59e | 5.68±0.21e | 苦味 | |

| 亮氨酸a | 11.9±1.44c | 10.49±0.53c | 苦味 | |

| 苯丙氨酸a | 0.63±0.10h | 5.53±0.35e | 无味 | |

| 组氨酸 | 4.72±0.32f | 2.90±0.41g | 苦味 | |

| 精氨酸 | 0.18±0.02i | 0.23±0.01k | 苦味 | |

| 半胱氨酸 | 1.16±0.03g | 1.11±0.06j | 酸味 | |

| 酪氨酸 | 5.76±0.22ef | 1.50±0.12j | 甜味 | |

| 赖氨酸a | 14.66±0.73b | 9.02±1.02c | 甜味 | |

| 有机酸 | 酒石酸 | 0.66±0.07c | 0.49±0.05a | 酸味 |

| 苹果酸 | 1.86±0.09b | 0.48±0.02a | 酸味 | |

| VC | 0.11±0.06e | 0.05±0.01d | 酸味 | |

| 乙酸 | 0.74±0.02c | 0.36±0.01b | 酸味 | |

| 柠檬酸 | 2.68±0.25a | 0.37±0.04b | 酸味 | |

| 琥珀酸 | 0.43±0.01d | 0.24±0.01c | 鲜味 | |

| 核苷酸 | 5'-CMP | 3.70±0.08a | 0.99±0.02a | 无味 |

| 5'-UMP | 1.50±0.05b | 0.11±0.01d | 无味 | |

| 5'-GMP | 0.37±0.01d | 0.11±0.01d | 鲜味 | |

| 5'-IMP | 0.70±0.02c | 0.37±0.01b | 鲜味 | |

| 5'-AMP | 0.13±0.01e | 0.09±0.01d | 鲜味 | |

| 5'-XMP | 0.12±0.01e | 0.17±0.01c | 鲜味 | |

表2 大球盖菇干制样品中滋味成分含量

Table 2 Taste component contents in dried samples of S. rugosoannulata mushrooms

| 滋味成分类别 | 滋味成分 | 含量/(mg·g-1干重) | 滋味特征 | |

|---|---|---|---|---|

| HPD | RFD | |||

| 氨基酸 | 天冬氨酸 | 0.65±0.01h | 1.88±0.12h | 甜味、鲜味 |

| 谷氨酸 | 25.23±0.80a | 23.67±2.84a | 鲜味 | |

| 苏氨酸a | 8.93±0.59d | 6.61±0.17d | 甜味 | |

| 丝氨酸 | 23.76±2.36a | 15.58±0.59b | 甜味 | |

| 甘氨酸 | 4.80±0.62f | 4.12±0.21f | 甜味 | |

| 丙氨酸 | 14.42±0.24b | 14.09±0.90b | 甜味 | |

| 脯氨酸 | 4.89±0.68f | 5.79±0.37e | 甜味 | |

| 缬氨酸a | 12.29±0.31c | 10.78±1.29c | 甜味、苦味 | |

| 甲硫氨酸a | 0.62±0.04h | 0.31±0.08k | 甜味、苦味 | |

| 异亮氨酸a | 6.61±0.59e | 5.68±0.21e | 苦味 | |

| 亮氨酸a | 11.9±1.44c | 10.49±0.53c | 苦味 | |

| 苯丙氨酸a | 0.63±0.10h | 5.53±0.35e | 无味 | |

| 组氨酸 | 4.72±0.32f | 2.90±0.41g | 苦味 | |

| 精氨酸 | 0.18±0.02i | 0.23±0.01k | 苦味 | |

| 半胱氨酸 | 1.16±0.03g | 1.11±0.06j | 酸味 | |

| 酪氨酸 | 5.76±0.22ef | 1.50±0.12j | 甜味 | |

| 赖氨酸a | 14.66±0.73b | 9.02±1.02c | 甜味 | |

| 有机酸 | 酒石酸 | 0.66±0.07c | 0.49±0.05a | 酸味 |

| 苹果酸 | 1.86±0.09b | 0.48±0.02a | 酸味 | |

| VC | 0.11±0.06e | 0.05±0.01d | 酸味 | |

| 乙酸 | 0.74±0.02c | 0.36±0.01b | 酸味 | |

| 柠檬酸 | 2.68±0.25a | 0.37±0.04b | 酸味 | |

| 琥珀酸 | 0.43±0.01d | 0.24±0.01c | 鲜味 | |

| 核苷酸 | 5'-CMP | 3.70±0.08a | 0.99±0.02a | 无味 |

| 5'-UMP | 1.50±0.05b | 0.11±0.01d | 无味 | |

| 5'-GMP | 0.37±0.01d | 0.11±0.01d | 鲜味 | |

| 5'-IMP | 0.70±0.02c | 0.37±0.01b | 鲜味 | |

| 5'-AMP | 0.13±0.01e | 0.09±0.01d | 鲜味 | |

| 5'-XMP | 0.12±0.01e | 0.17±0.01c | 鲜味 | |

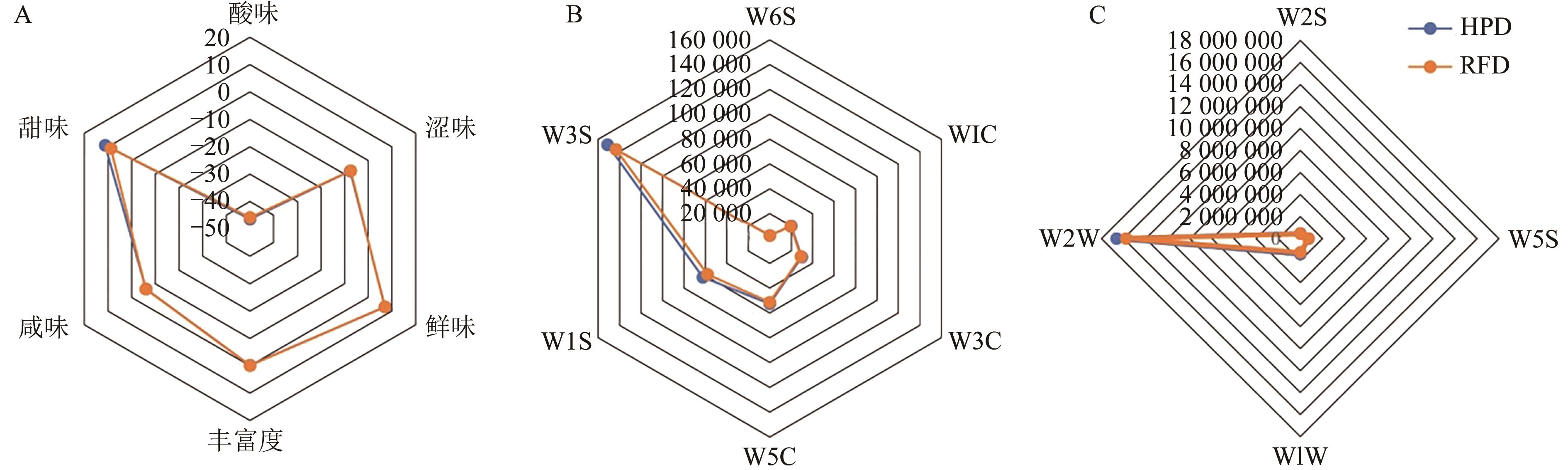

图7 大球盖菇干制样品电子舌和电子鼻风味分析A:干制样品的电子舌风味分析雷达图;B:干制样品的W6S、W1C、W3C、W5C、W1S、W3S 6种电子鼻传感器风味分析雷达图;C:干制样品的W2S、W5S、W1W、W2W 4种电子鼻传感器风味分析雷达图。

Fig. 7 E-tongue and e-nose flavor analysis of S. rugosoannulata mushroom dried samples

| 样品 | 硬度 | 黏附性 | 弹性 | 咀嚼性 | 胶黏性 | 内聚性 | 易碎性 | 回弹性 |

|---|---|---|---|---|---|---|---|---|

| HPD | 1 124.18±192.08 | 9.32±1.35 | 0.78±0.11 | 375.33±10.33 | 502.92±13.33 | 0.45±0.08 | 689.8±51.99 | 0.06±0.01 |

| RFD | 1 597.08±196.65 | 5.08±1.26 | 0.88±0.12 | 679.08±42.64 | 773.61±46.39 | 0.50±0.13 | 1 168.37±178.15 | 0.05±0.01 |

表3 大球盖菇干制样品质构分析

Table 3 Quality constitutive analysis of S. rugosoannulata mushroom dried samples

| 样品 | 硬度 | 黏附性 | 弹性 | 咀嚼性 | 胶黏性 | 内聚性 | 易碎性 | 回弹性 |

|---|---|---|---|---|---|---|---|---|

| HPD | 1 124.18±192.08 | 9.32±1.35 | 0.78±0.11 | 375.33±10.33 | 502.92±13.33 | 0.45±0.08 | 689.8±51.99 | 0.06±0.01 |

| RFD | 1 597.08±196.65 | 5.08±1.26 | 0.88±0.12 | 679.08±42.64 | 773.61±46.39 | 0.50±0.13 | 1 168.37±178.15 | 0.05±0.01 |

| 1 | 陈万超,李文,吴迪,等.基于成分轮廓数据的大球盖菇干制风味品质综合分析评价[J].食品科学,2023,44(6):311-319. |

| CHEN W C, LI W, WU D, et al.. Comprehensive analysis and evaluation of flavor quality of dried Stropharia rugosoannulata based on component profile data[J]. Food Sci., 2023, 44(6): 311-319. | |

| 2 | 李佳霖,杨焱,李文,等.大球盖菇干制过程香气变化规律及与关键酶促反应的关联性[J].食品科学技术学报,2023,41(1):30-42. |

| LI J L, YANG Y, LI W, et al.. Aroma change and its relationship with key enzymatic reactions in drying process of Stropharia rugosoannulata [J]. J. Food Sci. Technol., 2023, 41(1): 30-42. | |

| 3 | 陈荣荣,李文,吴迪,等.大球盖菇生长发育过程中营养、质构和滋味特征的动态变化[J].食用菌学报,2022,29(4):42-54. |

| CHEN R R, LI W, WU D, et al.. Nutrients, texture and taste characteristics of Stropharia rugosoannulata during growth and development[J]. Acta Edulis Fungi, 2022, 29(4): 42-54. | |

| 4 | 陈万超,李文,吴迪,等.11个主栽品种香菇可溶性糖和有机酸测定及滋味品质评价[J].食品工业科技,2022,43(7):273-279. |

| CHEN W C, LI W, WU D, et al.. Determination of soluble sugar and organic acid components and evaluation of taste quality of 11 main cultivars of Lentinula edodes [J]. Sci. Technol. Food Ind., 2022, 43(7): 273-279. | |

| 5 | 李文,冯杰,马海乐,等.基于靶向代谢产物分析解析大球盖菇发酵特征性风味物质及其呈味特性[J].食品安全质量检测学报,2022,13(9):2736-2744. |

| LI W, FENG J, MA H L, et al.. Analysis of the characteristic flavor components and flavor characteristics of the fermentation of Stropharia rugoso-annulata based on targeted metabolite assay[J]. J. Food Saf. Qual., 2022, 13(9): 2736-2744. | |

| 6 | 代文婷,吉建邦,康效宁,等.槟榔干制技术研究进展[J].食品工业,2021,42(3):258-262. |

| DAI W T, JI J B, KANG X N, et al.. Research progress of Areca nuts drying technology[J]. Food Ind., 2021, 42(3): 258-262. | |

| 7 | 林萍,姚娜娜,车凤斌,等.5种干制方式对大果沙棘干燥特性及品质的影响[J].食品工业科技,2022,43(4):41-48. |

| LIN P, YAO N N, CHE F B, et al.. Effects of five different drying methods on drying characteristic and quality of Hippophae rhamnoides [J]. Sci. Technol. Food Ind., 2022, 43(4): 41-48. | |

| 8 | 黄燕芬,肖默艳,王东伟,等.荔枝果肉热泵干燥及其储藏特性研究[J].保鲜与加工,2020,20(6):44-50. |

| HUANG Y F, XIAO M Y, WANG D W, et al.. Study on drying and storage characteristics of Litchi aril by heat pump drying[J]. Storage Proc., 2020, 20(6): 44-50. | |

| 9 | 李昊杰,张德润,董京磊,等.香葱干制技术研究进展[J].中国调味品,2020,45(3):198-200. |

| LI H J, ZHANG D R, DONG J L, et al.. Research progress on the drying technology of chives[J]. China Condiment, 2020, 45(3): 198-200. | |

| 10 | 杨兵,梅小飞,阚建全.热泵干制对青花椒色差和品质的影响及工艺优化[J].食品与发酵工业,2019,45(12):140-145+151. |

| YANG B, MEI X F, KAN J Q. Effects of heat pump drying on chromatism and quality of Zanthoxylum L. and process optimization[J]. Food Ferment. Ind., 2019, 45(12): 140-145+151. | |

| 11 | 张乐道,樊丹丹,任广跃,等.热泵干燥和远红外干燥干制怀山药溶出性研究[J].食品科技,2018,43(8):81-84. |

| ZHANG L D, FAN D D, REN G Y, et al.. The solubleness research of Chinese yam under heat pump drying and far-infrared drying[J]. Food Sci. Technol., 2018, 43(8): 81-84. | |

| 12 | 黄隆胜,刘军,龚丽,等.柿饼热泵干制工艺试验研究[J].现代农业装备,2017,38(4):17-19. |

| HUANG L S, LIU J, GONG L, et al.. Experimental study on heat pump drying technology of persimmon[J]. Mod. Agric. Equip., 2017, 38(4): 17-19. | |

| 13 | 王安建,刘丽娜,魏书信,等.响应面法优化香菇热泵干燥工艺[J].食品科技,2016,41(3):62-66. |

| WANG A J, LIU L N, WEI S X, et al.. Optimization of heat-pump drying process of Lentinus edodes by response surface method[J]. Food Sci. Technol., 2016, 41(3): 62-66. | |

| 14 | 吕飞,沈军樑,丁玉庭.贻贝热泵干制过程中的品质变化研究[J].现代食品科技,2015,31(6):142-149. |

| LV F, SHEN J L, DING Y T. Changes in mussel quality during heat-pump drying[J]. Mod. Food Sci. Technol., 2015, 31(6): 142-149. | |

| 15 | 徐玉娟,邓彩玲,林羡,等.龙眼高温热泵干制过程中主要活性成分变化研究[J].热带作物学报,2014,35(6):1215-1220. |

| XU Y J, DENG C L, LIN X, et al.. Changes of main active compounds of Longan during high temperature heat pump drying process[J]. Chin. J. Trop. Crops, 2014, 35(6): 1215-1220. | |

| 16 | HAWLADER M N A, PERERA C O, TIAN M. Comparison of the retention of 6-gingerol in drying of ginger under modified atmosphere heat pump drying and other drying methods[J]. Dry. Technol., 2006, 24(1): 51-56. |

| 17 | CHUA K J, CHOU S K, HO J C, et al.. Cyclic air temperature drying of guava pieces: effects on moisture and ascorbic acid contents[J]. Food Bioprod. Proc., 2000, 78(2): 72-78. |

| 18 | NERI T A N, JUNG H C, JANG S K, et al.. Nutritional quality variation in dried Pacific Oyster (Crassostrea gigas) using hybrid-pump dryer under different heating treatment[J]. Food Sci. Biotechnol., 2021, 30(5): 643-652. |

| 19 | XU Y, ZANG Z, ZHANG Q, et al.. Characteristics and quality analysis of radio frequency-hot air combined segmented drying of wolfberry (Lycium barbarum)[J/OL]. Foods, 2022, 11(11): 1645[2024-04-13]. . |

| 20 | 马哈默德·纳韦德,张悦,尹君,等.热风辅助射频间歇干燥对稻米理化特性的影响[J].农业工程学报,2022,38(S1):331-338. |

| NAVEED M, ZHANG Y, YIN J, et al.. Effects of hot air assisted radio frequency intermittent drying with tempering on the physicochemical properties of rough rice[J]. Trans. Chin. Soc. Agric. Eng., 2022, 38(S1): 331-338. | |

| 21 | 林雅文,董双,谭卓弘,等.射频联合热风干燥对南美白对虾干燥特性及品质研究[C]//中国食品科学技术学会.第二十届年会论文集.长沙, 2023:419-420. |

| LIN Y, DONG S, TAN Z H, et al.. Study of radio frequency combined hot air drying on drying characteristics and quality of Penaeus vannamei [C]// Chinese Institute of Food Science and Technology. Abstracts of the 20th Annual Meeting of CIFST. Changsha, 2023:419-420. | |

| 22 | 栗丽,王博,王玉川,等.不同干燥方式对降糖山楂条干燥特性及品质影响研究[J].食品与发酵工业,2023,49(12):10-16. |

| LI L, WANG B, WANG Y C, et al.. Effects of different drying methods on drying characteristics and quality of sugar-reduced hawthorn stick[J]. Food Ferment. Ind., 2023, 49(12): 10-16. | |

| 23 | 牛玉宝,姚雪东,肖红伟,等.射频辅助热风干燥对红枣脆片质构特性和微观结构的影响[J].农业工程学报,2022,38(2):296-306. |

| NIU Y B, YAO X D, XIAO H W, et al.. Effects of radio frequency assisted hot air drying on the texture and microstructure of jujube slices[J]. Trans. Chin. Soc. Agric. Eng., 2022, 38(2): 296-306. | |

| 24 | YAO X, ZANG Y, GU J, et al.. Microstructure analysis and quality evaluation of jujube slices dried by hot air combined with radio frequency heat treatment at different drying stages[J/OL]. Foods, 2022, 11(19): 3086[2024-04-13]. . |

| 25 | CHITSUTHIPAKORN K, THANAPORNPOONPONG S N. Effect of large-scale paddy rice drying process using hot air combined with radio frequency heating on milling and cooking qualities of milled rice[J/OL]. Foods, 2022, 11(4):519[2024-04-13]. . |

| 26 | TURAN S, ELIK DEMIR A, GÖĞÜŞ F, et al.. Hot-air-assisted radiofrequency drying of olive pomace and its effect on the quality of olive pomace oil[J/OL]. Foods, 2023, 12(18): 3515[2024-04-13]. . |

| [1] | 李雨薇, 吕家硕, 于一凡, 刘晓晖, 刘成珍. 黄曲霉毒素降解技术研究及应用进展[J]. 生物技术进展, 2023, 13(6): 853-862. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

版权所有 © 2021《生物技术进展》编辑部